General Details

STANDARD FEATURES AND BENEFITS

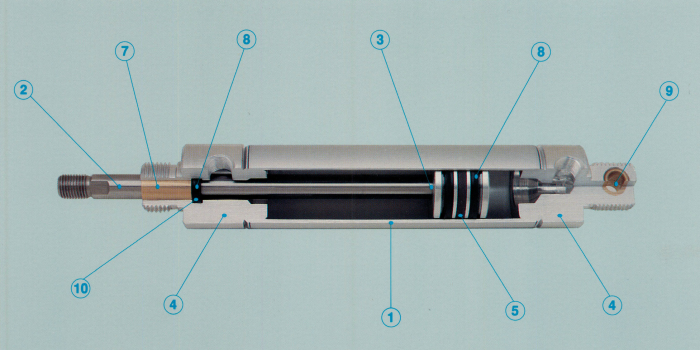

1 Stainless Steel Cylinder Body: Type 304 Stainless Steel manufactured to special mill specifications and tolerances to insure a long cylinder life.

2 Stainless Steel Rod: Ground & Polished Type 303 Stainless Steel rods are standard on the Stainless Steel Series. All rods 1/4" diameter and larger have wrench flats and stress relief grooves.

3 Piston Rod Assembly: Piston rods are threaded, anaerobically sealed, and machine staked into the piston for triple protection.

4 End Caps, Piston: High strength aluminum alloy.

5 Magnet for Sensing Switch Actuation: Optional, refer to American Cylinder’s MFC® catalog for details.

6 Springs: Springs for spring action cylinders are made from music wire and designed for millions of cycles. Special spring forces are available.

7 Rod Guide Bushing: Standard on all models. The oil impregnated sintered bronze bushing increases the life of the cylinder rod and provides a non-abrasive bearing surface.

8 Buna-N U-Cup Rod & Piston Seals: U-Cup seals provide low breakaway friction and maximize cylinder life expectancy. Standard Buna-N seals are recommended for operating temperatures of -20°F (-25°C) to 200°F (95°C). Fluoroelastomer seals are available for higher temperature applications.

9 Pivot Pin/Pivot Bushing: Stainless Steel Series cylinders are shipped with plated steel pivot pins as standard. Sintered bronze pivot bushings are available as an alternative standard option. (5/16", 1-3/4", 2" & 3" bores supplied with pivot bushing only.)

10 Rod Seal: Precision machined rod seal groove provides a smooth sealing surface while positively retaining the seal without requiring additional components and relying on press fit containment.

11 Pre-lubricated: All cylinders are factory lubricated with a special high endurance oil mixture.

12 Pre-Tested: The quality of each cylinder is assured by testing each unit for leakage prior to shipment. Quality control provides added value to American cylinders.